The PFN2023 conference recently gathered industry experts from the project freight and logistics sector to discuss ways to improve efficiency and reduce costs.

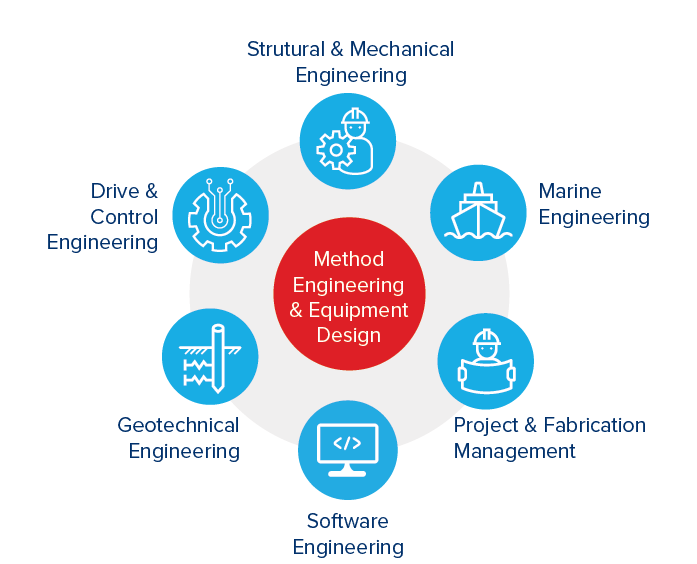

One panel-discussion that stood out was trangineering, a relative new discipline that combines transportation and engineering principles to optimize project cargo and logistics processes.

In this article, we’ll explore the insights shared during a panel discussion at the conference, diving into how trangineering, also known as method engineering, contributes to cost savings, provides examples of design changes resulting in significant cost reductions, highlights the benefits of involving transport engineers in the early stages of projects, showcases successful implementations, outlines training requirements, explains how trangineering enhances flexibility and efficiency, and discusses other innovative methods in project freight and logistics operations.

The panel-discussion at the PFN Project Freight Network conference was held on 5th of June at the PFN2023 conference with Mr. Dimitrios Ntroumpis, lead engineer at TWD in Rotterdam, Netherlands.

Cost Savings in the Project Cargo and Logistics Sector

Trangineering, or method engineering, plays a vital role in achieving cost savings within the project cargo and logistics sector. By applying systematic process analysis and design, organizations can identify inefficiencies, bottlenecks, and areas of waste in their transportation and logistics processes. This allows them to implement targeted improvements, streamline operations, and optimize resource utilization, resulting in significant cost reductions. Through careful planning, route optimization, load consolidation, and effective coordination, trangineering helps minimize transportation delays, avoid unnecessary storage, and decrease fuel consumption, ultimately reducing project costs.

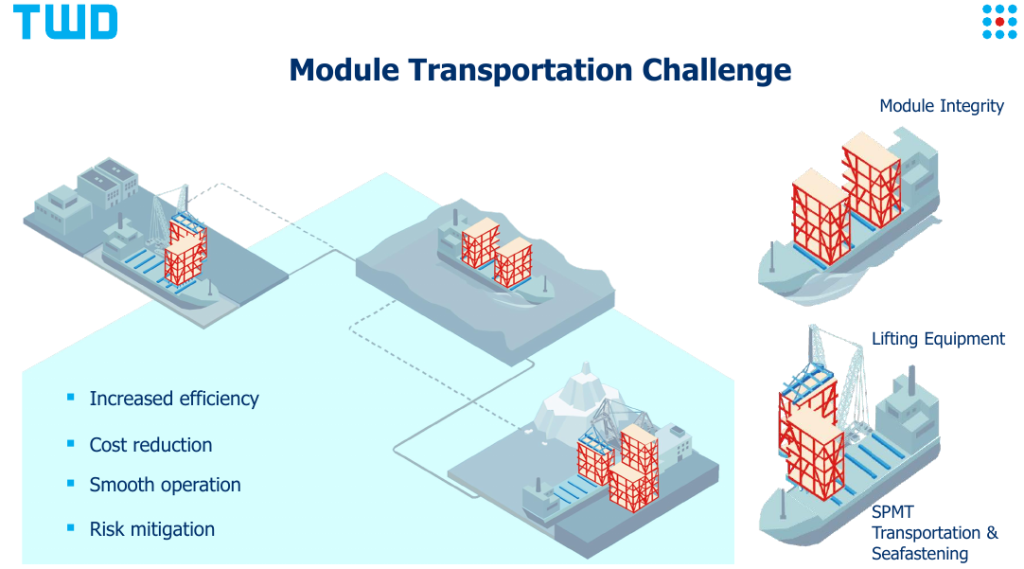

Design Changes for Cost Reductions in Equipment Transport

Method engineering, including trangineering, has led to specific design changes that result in significant cost reductions in equipment transport. For example, innovative loading and securing techniques have been implemented to optimize space utilization within cargo vessels, trucks, or aircraft. By making efficient use of available volume and reducing empty spaces, companies can transport more equipment in a single trip, thus reducing transportation costs. Additionally, strategic use of modular designs and standardized packaging solutions can minimize handling and assembly time, leading to faster and more cost-effective equipment deployment.

Benefits of Involving Transport Engineers in Project Design and Engineering Stages

Involving transport engineers, also known as trangineers, in the early stages of project design and engineering offers several key benefits. Firstly, their expertise enables the early identification of transportation requirements and constraints, allowing for proactive consideration of logistics during the project planning phase. Trangineers collaborate closely with project designers and engineers to optimize equipment dimensions, select appropriate transportation modes, and design infrastructure that facilitates efficient loading and unloading. By involving trangineers from the outset, transportation and logistics aspects are seamlessly integrated into the overall project design, resulting in improved efficiency, reduced costs, and timely delivery.

Successful Implementations and Lessons Learned

Several companies have successfully implemented method engineering, including trangineering, in their engineering departments, achieving positive outcomes and valuable lessons. For instance, Company X applied trangineering principles to a large-scale infrastructure project, resulting in a 15% reduction in transportation costs and a 20% decrease in project completion time. A key lesson learned was the importance of early collaboration between trangineers, designers, and engineers to optimize transportation routes, consider load constraints, and incorporate logistics planning into the project timeline. Successful implementations highlighted the need for ongoing monitoring, feedback loops, and continuous improvement to adapt to changing project requirements and optimize transportation efficiency.

Training and Expertise for Effective Trangineering Implementation

To effectively implement trangineering in engineering departments, professionals require specialized training and expertise. This includes a strong foundation in transportation and logistics principles, knowledge of applicable regulations and industry standards, and proficiency in process analysis and design techniques. Trangineers must possess a comprehensive understanding of various transportation modes, equipment handling practices, and loading/unloading methodologies. Additionally, proficiency in route optimization software, project management, and effective communication skills are vital for successful trangineering implementation. Continuous learning, staying updated with industry trends, and collaborating with cross-functional teams are essential for trangineers to deliver optimal results.

Enhancing Flexibility and Efficiency in Equipment Transportation

Trangineering significantly enhances flexibility and efficiency in the transportation of equipment to job sites. By utilizing advanced planning techniques, such as dynamic routing algorithms and real-time monitoring systems, trangineers can adapt transportation plans to changing conditions and unforeseen circumstances. This enables them to optimize transportation schedules, respond to last-minute changes, and minimize disruptions. Furthermore, leveraging technology solutions, such as Internet of Things (IoT) sensors, trangineers can monitor equipment condition, track its location, and proactively address maintenance needs. These capabilities enhance efficiency, reduce downtime, and ensure the timely delivery of equipment to job sites.

Limitations and Challenges of Trangineering

While trangineering offers numerous benefits, it’s important to acknowledge its limitations and challenges. Trangineering may face constraints when dealing with oversized or specialized equipment, where transportation options are limited. Additionally, regulatory compliance, customs procedures, and varying transportation infrastructures across regions can present hurdles that require careful consideration. Moreover, trangineering implementation requires cross-functional collaboration, which may pose challenges in organizations with siloed departments. Overcoming these limitations demands effective communication, collaboration, and adaptability, as well as building strong relationships with transportation service providers, customs authorities, and other stakeholders.

Factors Determining Suitability of Trangineering in the Freight and Logistics Sector

The suitability of trangineering for a particular project in the freight and logistics sector depends on several factors. Firstly, the scale and complexity of the project influence the potential cost savings and efficiency gains achievable through trangineering. Projects involving substantial equipment transportation requirements, multiple locations, or time-critical deliveries are ideal candidates. Secondly, the availability of skilled trangineers within the organization or access to external expertise is crucial. Finally, the commitment of the organization to invest in training, technology solutions, and process improvements plays a significant role in determining the feasibility and success of trangineering implementation.

Other Innovative Approaches in Project Freight and Logistics Operations

While trangineering is an effective approach, other innovative methods and approaches have also proven successful in improving project freight and logistics operations. For instance, the implementation of advanced data analytics and predictive modeling enables proactive identification of transportation bottlenecks, enhances demand forecasting, and optimizes resource allocation. Additionally, the utilization of autonomous vehicles and drones in logistics operations can reduce human error, improve safety, and enable faster delivery. Furthermore, the adoption of blockchain technology enhances supply chain visibility, transparency, and trust among stakeholders, facilitating smoother project cargo management.

Final Word

The PFN2023 conference highlighted the significant impact of trangineering, or method engineering, in optimizing project cargo and logistics processes. By applying systematic analysis, design, and implementation, organizations can achieve substantial cost savings, improve efficiency, and enhance delivery timelines. Successful trangineering implementation requires collaboration, ongoing improvement, and the utilization of technology solutions. While trangineering presents challenges, its benefits in terms of flexibility, efficiency, and cost reduction are undeniable. As the project freight and logistics sector evolves, embracing innovative approaches such as trangineering will become increasingly important for organizations to maintain a competitive edge.